Switching from CANopen to EtherCAT

trait de séparation

Reading time : 6 minutes

In this article, acontis highlights some of the key advantages reported by their clients when switching from traditional fieldbuses like CANopen or DeviceNet to EtherCAT.

As a direct comparison of networks would lead to a kind of theoretical data analysis, Acontis emphasizes some of the differences and benefits using real-world use cases.

- Why Choose CAN/CANopen and EtherCAT?

- How to Identify the Reason for the Switch?

- First Advantage: Achieving Better Product Quality through Greater Precision

- Are there other examples where fast communication helps improve accuracy?

Why Choose CAN/CANopen and EtherCAT?

Since the second half of the 1990s, CANopen has been one of the most important fieldbuses in mechanical engineering, medical technology, and many other applications, ranging from small devices like vending machines to large-scale systems such as elevators or ship automation. It has been implemented in numerous programmable logic controllers and even more embedded or PC-based controllers.

EtherCAT was launched in 2003 as an “Ethernet fieldbus” and is today the most successful industrial Ethernet implementation—boasting over 7,000 members in the user organization and nearly 80 million nodes in the field. EtherCAT uses proven ideas from the fieldbus world—such as line topology and support for protocol elements and known data structures like CoE (CANopen over EtherCAT)—and enhances them with Ethernet features like very fast data throughput, extremely low latencies, and optimized transmission media.

With comparable communication concepts and data structures like CoE, EtherCAT is an ideal substitute for CANopen. The switch enables much more data to be safely transferred with many more participants in a much shorter time—while the system’s core concept remains intact: This means the same network topology can be used, and the EtherCAT controller can also be configured as a CANopen master on various platforms, ranging from small embedded controllers for manageable systems to industrial PCs for power-hungry applications like measurement systems or complex multi-axis robots.

EtherCAT was launched in 2003 as an “Ethernet fieldbus” and is today the most successful industrial Ethernet implementation—boasting over 7,000 members in the user organization and nearly 80 million nodes in the field. EtherCAT uses proven ideas from the fieldbus world—such as line topology and support for protocol elements and known data structures like CoE (CANopen over EtherCAT)—and enhances them with Ethernet features like very fast data throughput, extremely low latencies, and optimized transmission media.

With comparable communication concepts and data structures like CoE, EtherCAT is an ideal substitute for CANopen. The switch enables much more data to be safely transferred with many more participants in a much shorter time—while the system’s core concept remains intact: This means the same network topology can be used, and the EtherCAT controller can also be configured as a CANopen master on various platforms, ranging from small embedded controllers for manageable systems to industrial PCs for power-hungry applications like measurement systems or complex multi-axis robots.

How to identify the Reason for the Switch?

A simple "comparison of technical datasheets" between CANopen and EtherCAT can be quite comprehensive, as there are many different aspects to compare—and they carry different significance for every system using CAN or EtherCAT, especially since both networks are used in a variety of applications that differ significantly—from simple, small networks, such as those in vending machines, to large-scale networks with thousands of devices in complex machines like ships or fully integrated floor automation.

First Advantage: Achieving Better Product Quality through Greater Precision

Fast networks are generally considered beneficial for high-speed machines, such as fast drives or robots. However, a fast communication network also offers significant advantages for machines that might appear slow at first glance. Faster communication can serve as the foundation for speeding up the machine itself, but it can also be used to significantly increase the precision of machines, leading to higher-quality processing.

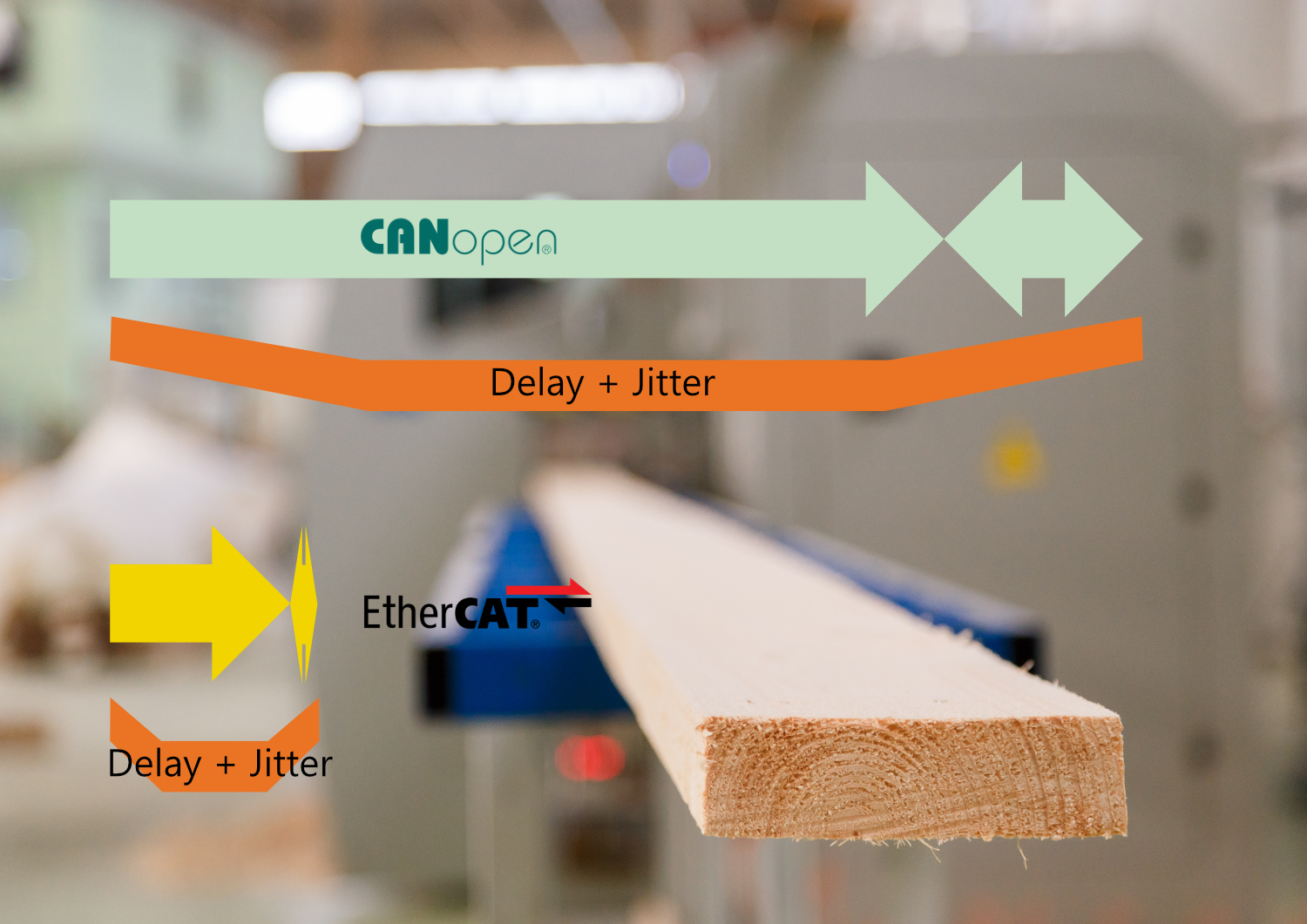

The following example illustrates how fast data rates and especially EtherCAT's extremely short cycle times can contribute to a significant improvement in precision and thus product quality: continuous material cutting. This is a typical process in many applications: cutting something to the exact length, whether it's rigid or flexible materials. Depending on the cutting mechanism and the cutting duration, multiple axes need to be tightly synchronized.

As a basic concept, when cutting continuously fed material, the response time of the cutting process determines the cutting precision. For example, with only 5 ms during cutting at a conveyor speed of 2 m/s, this results in a deviation of 10 mm in the cutting process. > If, for instance, 1-meter-long wooden strips are produced, the customer will not accept goods with fluctuating lengths of up to 1 cm, and therefore a length difference of 1%, whether visually or technically.

With a traditional fieldbus like CAN/CANopen, transmitting an 8-byte message at 250 kbit/s takes just under 500 µs in the best case (no bit stuffing, highest priority, bus free). If the bus is occupied or the message is not transmitted with the highest priority, transmission time is multiplied—in a well-designed system, an average transmission time of 5 to 10 ms can be assumed for important messages—which means, in this example, that the quality of the result does not meet the requirements. In many systems, transmission times below 20 ms cannot be achieved, and inevitable cycle time peaks lead to rejections.

EtherCAT offers a reliable cycle due to its specific transmission structure, etc., and enables extremely fast systems with high transmission speeds and simple software structures—with transmission times on the order of microseconds.

With a cycle time of 250 µs, the precision of the cutting process can be significantly increased—assuming a jitter (including software) of 500 µs, a precision of 1 mm can be achieved.

The following example illustrates how fast data rates and especially EtherCAT's extremely short cycle times can contribute to a significant improvement in precision and thus product quality: continuous material cutting. This is a typical process in many applications: cutting something to the exact length, whether it's rigid or flexible materials. Depending on the cutting mechanism and the cutting duration, multiple axes need to be tightly synchronized.

As a basic concept, when cutting continuously fed material, the response time of the cutting process determines the cutting precision. For example, with only 5 ms during cutting at a conveyor speed of 2 m/s, this results in a deviation of 10 mm in the cutting process. > If, for instance, 1-meter-long wooden strips are produced, the customer will not accept goods with fluctuating lengths of up to 1 cm, and therefore a length difference of 1%, whether visually or technically.

With a traditional fieldbus like CAN/CANopen, transmitting an 8-byte message at 250 kbit/s takes just under 500 µs in the best case (no bit stuffing, highest priority, bus free). If the bus is occupied or the message is not transmitted with the highest priority, transmission time is multiplied—in a well-designed system, an average transmission time of 5 to 10 ms can be assumed for important messages—which means, in this example, that the quality of the result does not meet the requirements. In many systems, transmission times below 20 ms cannot be achieved, and inevitable cycle time peaks lead to rejections.

EtherCAT offers a reliable cycle due to its specific transmission structure, etc., and enables extremely fast systems with high transmission speeds and simple software structures—with transmission times on the order of microseconds.

With a cycle time of 250 µs, the precision of the cutting process can be significantly increased—assuming a jitter (including software) of 500 µs, a precision of 1 mm can be achieved.

Thus, even with machines that may appear quite simple at first glance, the high-speed, high-precision control loops enabled by EtherCAT make a significant difference—not only in terms of "raw material yield" but also in terms of precise, high-quality products.

Are there other examples where fast communication contributes to improving precision?

Of course, there are many other examples where fast communication, short cycle times, and in some cases, the EtherCAT "Distributed Clock" function for synchronous operation are essential for the successful operation of machines:

Semiconductor Manufacturing → Lithography: Exposure times need to be extremely precise when exposing silicon wafers. Even the smallest deviations can lead to errors in integrated circuits.

The same applies to wafer etching processes: the duration of the etching processes must be precisely controlled to achieve the desired depth and shape of the structures.

Classic Industrial Automation — Robotic production control is just one example: the synchronized movement of multiple robots requires very precise time measurements. And when we think of welding robots, we add the welding processes themselves: welding time must be precisely tailored to the material properties to ensure a stable and safe connection.

There are also many examples in medical technologies where timing is critical, such as in tumor irradiation: the timing of the irradiation must be precise to the millisecond to spare healthy tissue and effectively combat the tumor.

Semiconductor Manufacturing → Lithography: Exposure times need to be extremely precise when exposing silicon wafers. Even the smallest deviations can lead to errors in integrated circuits.

The same applies to wafer etching processes: the duration of the etching processes must be precisely controlled to achieve the desired depth and shape of the structures.

Classic Industrial Automation — Robotic production control is just one example: the synchronized movement of multiple robots requires very precise time measurements. And when we think of welding robots, we add the welding processes themselves: welding time must be precisely tailored to the material properties to ensure a stable and safe connection.

There are also many examples in medical technologies where timing is critical, such as in tumor irradiation: the timing of the irradiation must be precise to the millisecond to spare healthy tissue and effectively combat the tumor.